Why Traditional Heating Fails Warehouses

The natural response is to install conventional heating. Gas-fired unit heaters, warm-air systems, or destratification fans that try to create a uniform temperature throughout the building.

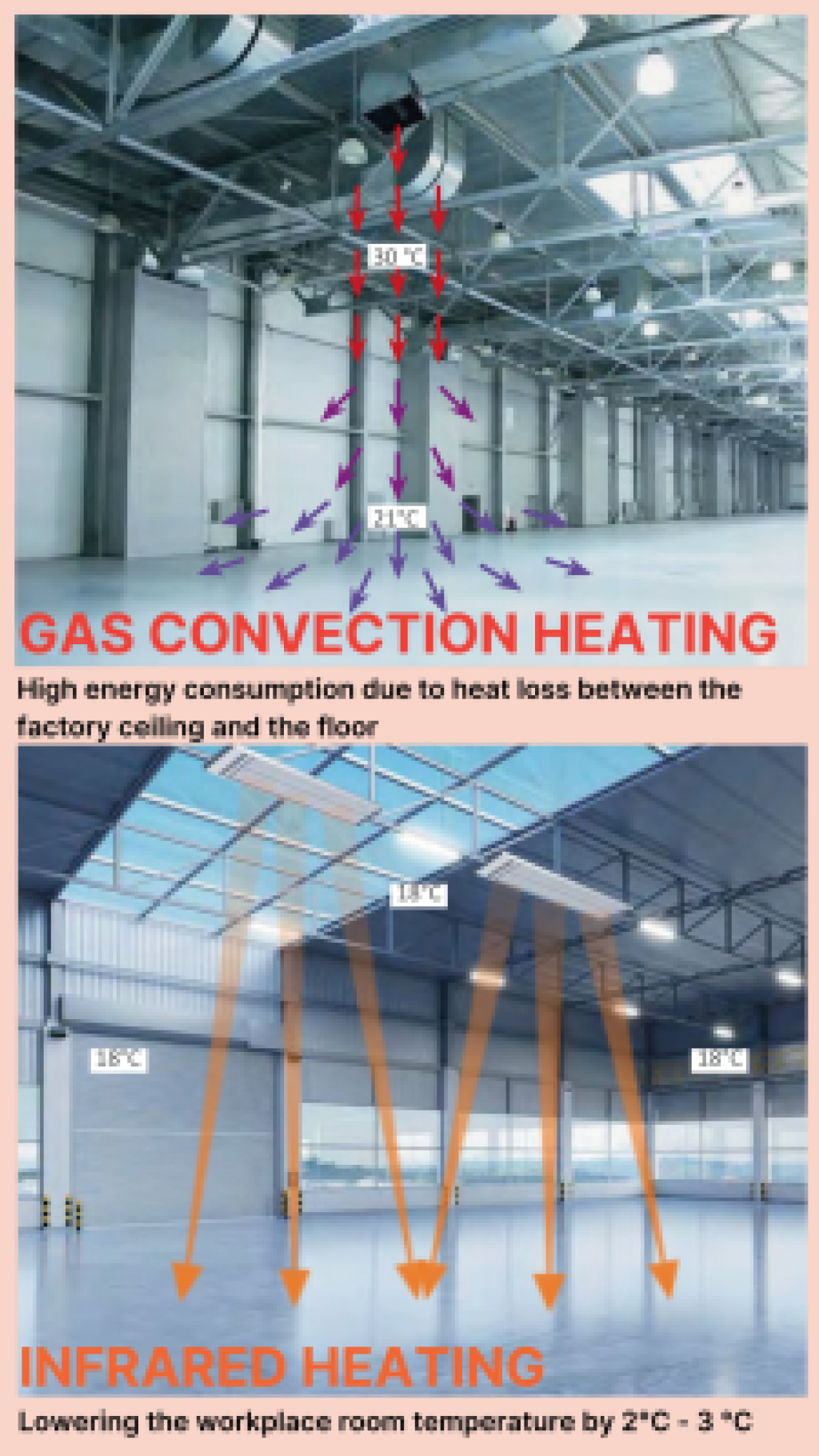

The problem is simple physics. Warm air rises. In a warehouse with 8-12 metre ceilings, your heating system spends most of its energy warming the upper cubic volume, the useless space above racking where nobody works. The warmth your staff needs stays stubbornly out of reach near the roof.

Worse, warehouse environments are inherently draughty. Loading bay doors open constantly. Roller shutters let in cold air. Every opening is a thermal breach. Traditional heating systems fight a perpetual losing battle, constantly trying to replace warm air that escapes, using enormous energy to achieve mediocre results at ground level where people actually work.

You end up with high energy bills, uncomfortable staff, and a system that fails precisely when it's needed most, during busy periods when doors stay open longest.